Product Information

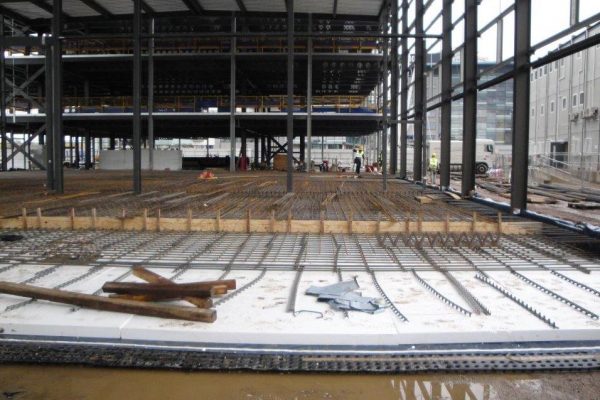

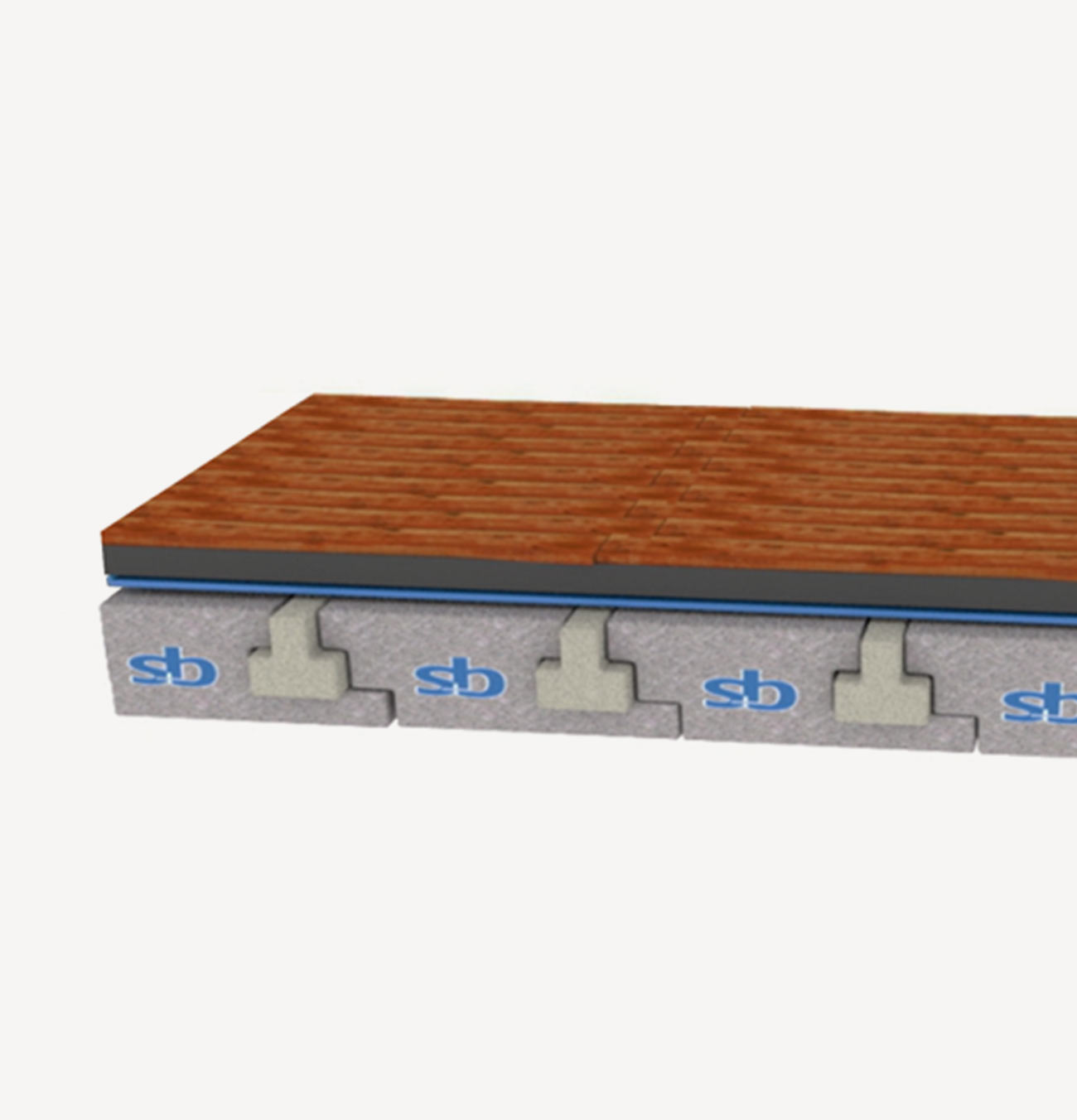

S and B EPS 70 flooring boards are designed for the insulation of ground floors in a variety of applications.

S and B EPS 100 flooring grade is recommended when high floor loadings are likely to be encountered in commercial applications and is suitable for use with either a solid or suspended ground floor and will meet the current building regulation U value requirements.

S and B EPS 150, EPS 200, EPS 250 and EPS 500 flooring grade is recommended when high floor loadings are likely to be encountered in commercial applications and is suitable for use with either a solid or suspended ground floor and will meet the current building regulation U value requirements.

The product is CFC and HCFC free lightweight closed cell material which is easy to install. It has a high insulation value and allows for rapid dry construction methods to be used in new or renovated dwellings and is available in either square edge.

Grades

S and B EPS floor modules are available in:

EPS 70E

EPS 100E

EPS 120E

EPS 150E

EPS 200E

EPS 250E

EPS 300E

EPS 500E

Lambdatherm® 70E

Lambdatherm® Elite

Lambdatherm® 120E

Lambdatherm® 150E

Advantages

- S and B EPS flooring offers excellent thermal performance providing savings in energy costs and higher comfort levels in dwellings.

- Maintains its thermal efficiency throughout the life of a building.

- Rapid construction: no specialised equipment or trades required.

- Saves up to a week in building time when used in an all-dry system with flooring grade chipboard.

- Available in a variety of thicknesses.

- Non-toxic, non-irritant, moisture resistant, easy to cut and fix.

- A+ green guide rating

To discover more about the benefits of S and B expanded polystyrene Flooring, call today on 0191 250 0818

Technical Information

| Features | Grades EPS | Lambdatherm® | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EPS70E | EPS100E | EPS120E | EPS150E | EPS200E | EPS250E | EPS300E | EPS500E | 70E | ELITE | 120E | 150E | |

Thermal Conductivity [k] value W/mk (10.C mean) |

0.038 | 0.036 | 0.036 | 0.035 | 0.034 | 0.033 | 0.033 | 0.033 | 0.031 | 0.030 | 0.031 | 0.031 |

Compress Strength kPa Min (at 10% compressivew strengths) |

70 | 100 | 120 | 150 | 200 | 250 | 300 | 500 | 70 | 100 | 120 | 150 |

Cross Breaking Strength kPa Min |

115 | 150 | 170 | 200 | 250 | 350 | 450 | 750 | 115 | 150 | 170 | 200 |

Safe Working Load kPa at 1% nominal compression |

21 | 45 | 45 | 70 | 90 | 100 | 120 | 190 | 21 | 45 | 45 | 70 |

Vapour Diffusion Resistance factor µ1 |

20-40 | 30-70 | 30-70 | 30-70 | 40-100 | 40-100 | 40-100 | 40-100 | 20-40 | 30-70 | 30-70 | 30-70 |

Vapour Permeability omg [pa.h.m] |

0.015 to 0.030 | 0.009 to 0.020 | 0.009 to 0.020 | 0.009 to 0.020 | 0.006 to 0.015 | 0.006 to 0.015 | 0.007 to 0.018 | 0.007 to 0.018 | 0.015 to 0.030 | 0.009 to 0.020 | 0.009 to 0.020 | 0.009 to 0.020 |

Colour Guide

| Identification / colour coding of products manufactured to BSEN 13163 | ||||||||

|---|---|---|---|---|---|---|---|---|

| EPS 70E | 2 x brown stripes & 1 red stripe | |||||||

| EPS 100E | 1 x black strip & 1 red stripe | |||||||

| EPS 120E | 2 x green stripes & 1 red stripe | |||||||

| EPS 150E | 1 x yellow strip & 1 red stripe | |||||||

| EPS 200E | 2 x black stripes & 1 red stripe | |||||||

| EPS 250E | 1 violet stripe & 1 red stripe | |||||||

| EPS 500E | 2 x black stripes & 1 red stripe | |||||||

Floor Pack Sizes

| Flooring 2400 x 1200mm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Qty/Pack | Cu-m per pack | Sq-m per pack | ||||||

| 2400 x 1200 x 25mm | 12 | 0.864 | 34.56 | |||||

| 2400 x 1200 x 30mm | 10 | 0.864 | 28.8 | |||||

| 2400 x 1200 x 50mm | 6 | 0.864 | 17.28 | |||||

| 2400 x 1200 x 75mm | 4 | 0.864 | 11.52 | |||||

| 2400 x 1200 x 100mm | 3 | 0.864 | 8.64 | |||||

| 2400 x 1200 x 150mm | 2 | 0.864 | 5.76 | |||||

Downloads

Case Study

FAQs

Question 1

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Question 2

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Question 3

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.