Advantages

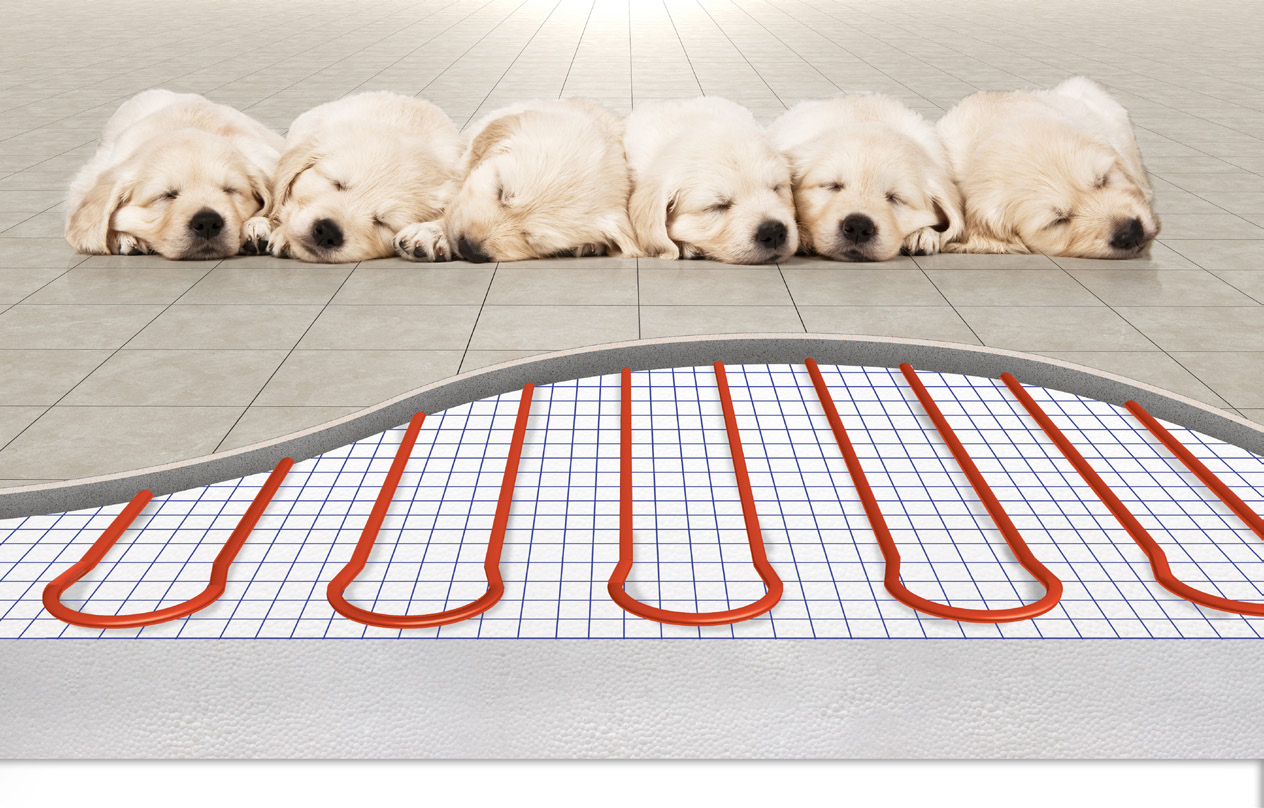

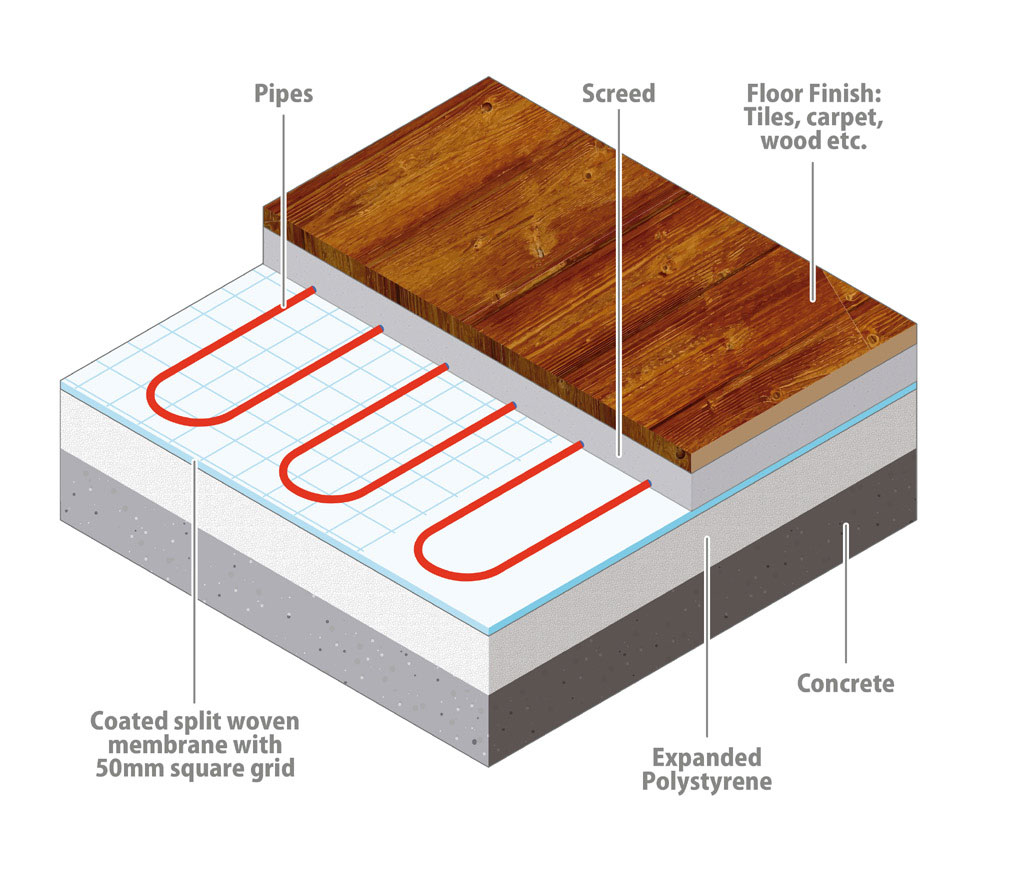

- Can accept all screeds

- Grooves for ease of pipe alignment

- 1.2m x 1.2m for speed of laying

- Lightweight

- Excellent price performance ratio

- Green guide A+ rating

Product Information

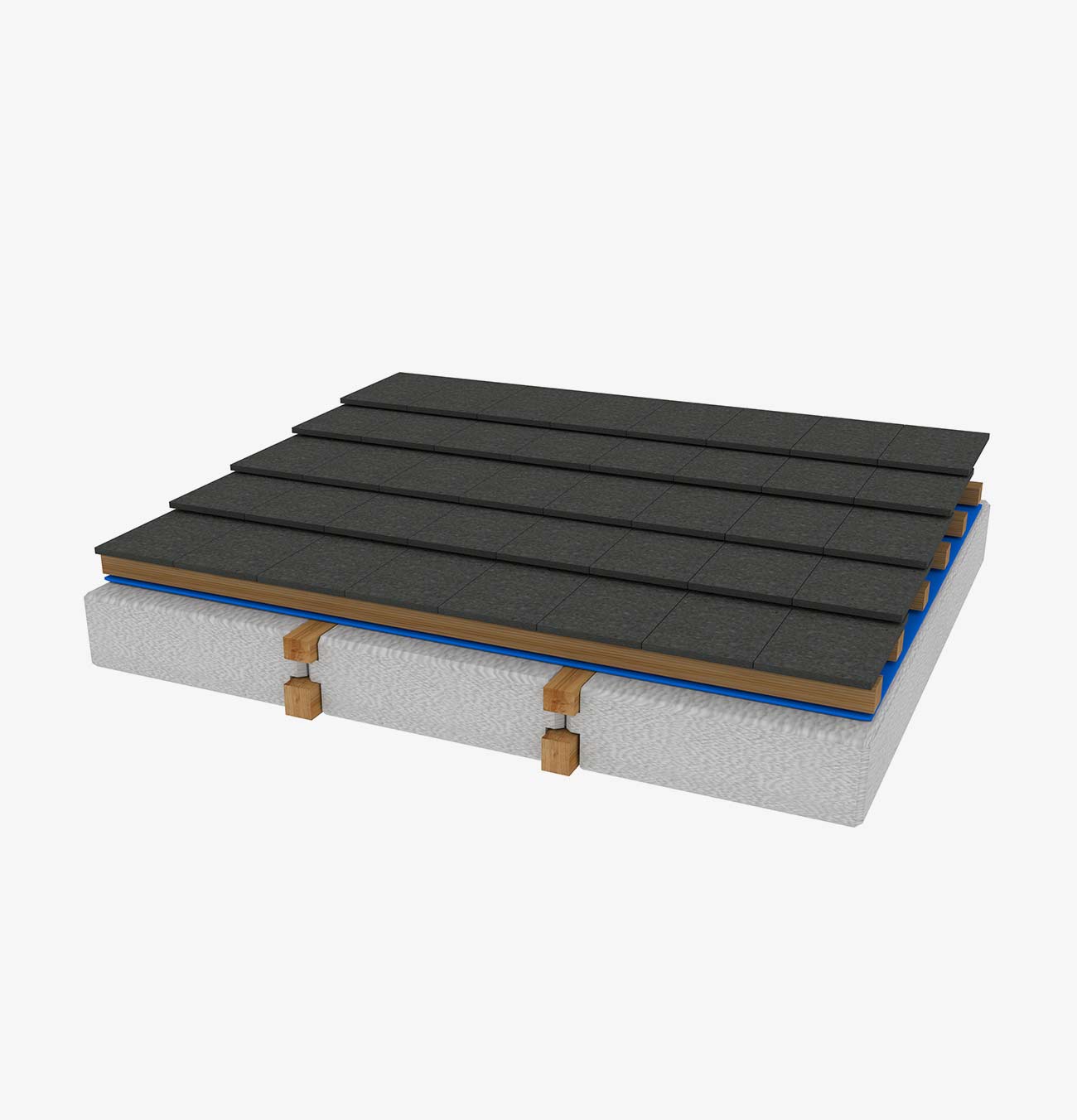

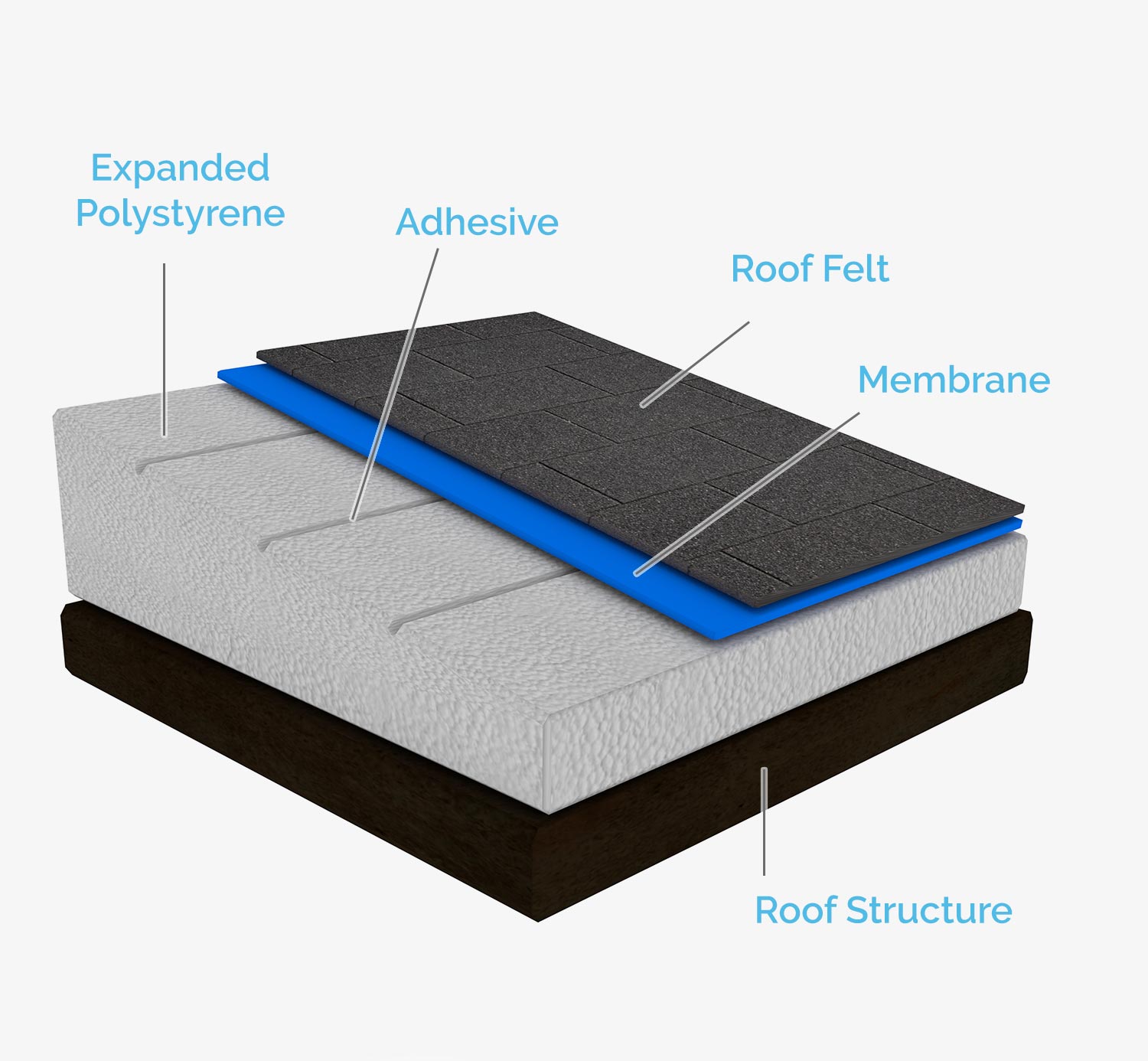

We manufacture a wide range of roofing insulation products to meet the various required applications. We work in conjunction with roof engineers and design teams to offer the complete design and supply package.

The main consideration for a specifier is to decide which weatherproof finish is required and then build up a compatible system to accommodate this, coupled with the need to take into account the effect of heat on the construction both during construction and after completion.

Other important issues involve the selection of a compatible adhesive, sealant and or mechanical fixing to bond the weatherproof membrane plus the control of water vapour. S and B EPS offer a wide range of systems that are available in a wide range of densities and thicknesses with, a square edge, shiplap or tongue and grooved edge detail.

Cut-to-falls insulation offers the ideal solution to refurbishment and ponding problems on existing buildings. Uniform thickness boards are suitable for roofs which have an existing fall incorporated and are unaffected by bacteria, fungi or moulds and maintain their thermal efficiency throughout the life of the building.

Compatibility:

S and B EPS roof insulation can be adapted to suit a wide range of applications including weatherproof roof membranes. Unlaminated expanded roof boards are suitable for use under EPDM/ butyl rubber roofing and some plastic type single layer membranes. Where the membrane is plasticised, a separating layer of fleece is required between the polystyrene and the membrane. Pre-felted boards are suitable where built up felt or high-performance roofing felts are used with mastic asphalt roofing, but care must be taken when laying in very high ambient temperatures (technical information available on request).

Grades

S and B EPS Roof boards are available in:

EPS 70E

EPS 100E

EPS 150E

EPS 200E

EPS 250E

EPS 300E

Lambdatherm® Elite

To discover more about the benefits of S and B Roofing Solutions, call today on 0191 250 0818

Technical Information

| Features | Grades EPS | Lambdatherm® | ||||||

|---|---|---|---|---|---|---|---|---|

| EPS70E | EPS100E | EPS150E | EPS200E | EPS250E | EPS300E | ELITE | 150E | |

Thermal Conductivity [k] value W/mk (10.C mean) |

0.038 | 0.036 | 0.035 | 0.034 | 0.033 | 0.033 | 0.030 | 0.031 |

Compress Strength kPa Min (at 10% compressivew strengths) |

70 | 100 | 150 | 200 | 250 | 300 | 100 | 150 |

Cross Breaking Strength kPa Min |

115 | 150 | 200 | 250 | 350 | 450 | 150 | 200 |

Safe Working Load kPa at 1% nominal compression |

21 | 45 | 70 | 90 | 100 | 120 | 45 | 70 |

Vapour Diffusion Resistance factor µ1 |

20-40 | 30-70 | 30-70 | 40-100 | 40-100 | 40-100 | 30-70 | 30-70 |

Vapour Permeability omg [pa.h.m] |

0.015 to 0.030 | 0.009 to 0.020 | 0.009 to 0.020 | 0.006 to 0.015 | 0.006 to 0.015 | 0.007 to 0.018 | 0.009 to 0.020 | 0.009 to 0.020 |

Colour Guide

| Identification / colour coding of products manufactured to BSEN 13163 | ||||||||

|---|---|---|---|---|---|---|---|---|

| EPS 70E | 2 x brown stripes & 1 red stripe | |||||||

| EPS 100E | 1 x black strip & 1 red stripe | |||||||

| EPS 120E | 2 x green stripes & 1 red stripe | |||||||

| EPS 150E | 1 x yellow strip & 1 red stripe | |||||||

| EPS 200E | 2 x black stripes & 1 red stripe | |||||||

| EPS 250E | 1 violet stripe & 1 red stripe | |||||||

| EPS 500E | 2 x black stripes & 1 red stripe | |||||||

Product Files

Case Study

FAQs

Question 1

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Question 2

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Question 3

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.