Advantages

- 1.2m lengths

- Easy to cut with hand saw

- Lightweight

- Excellent price performance ratio

- Green guide A+ rating

Product Information

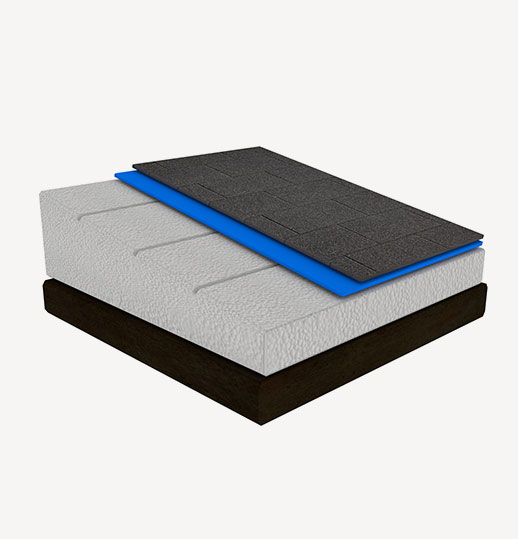

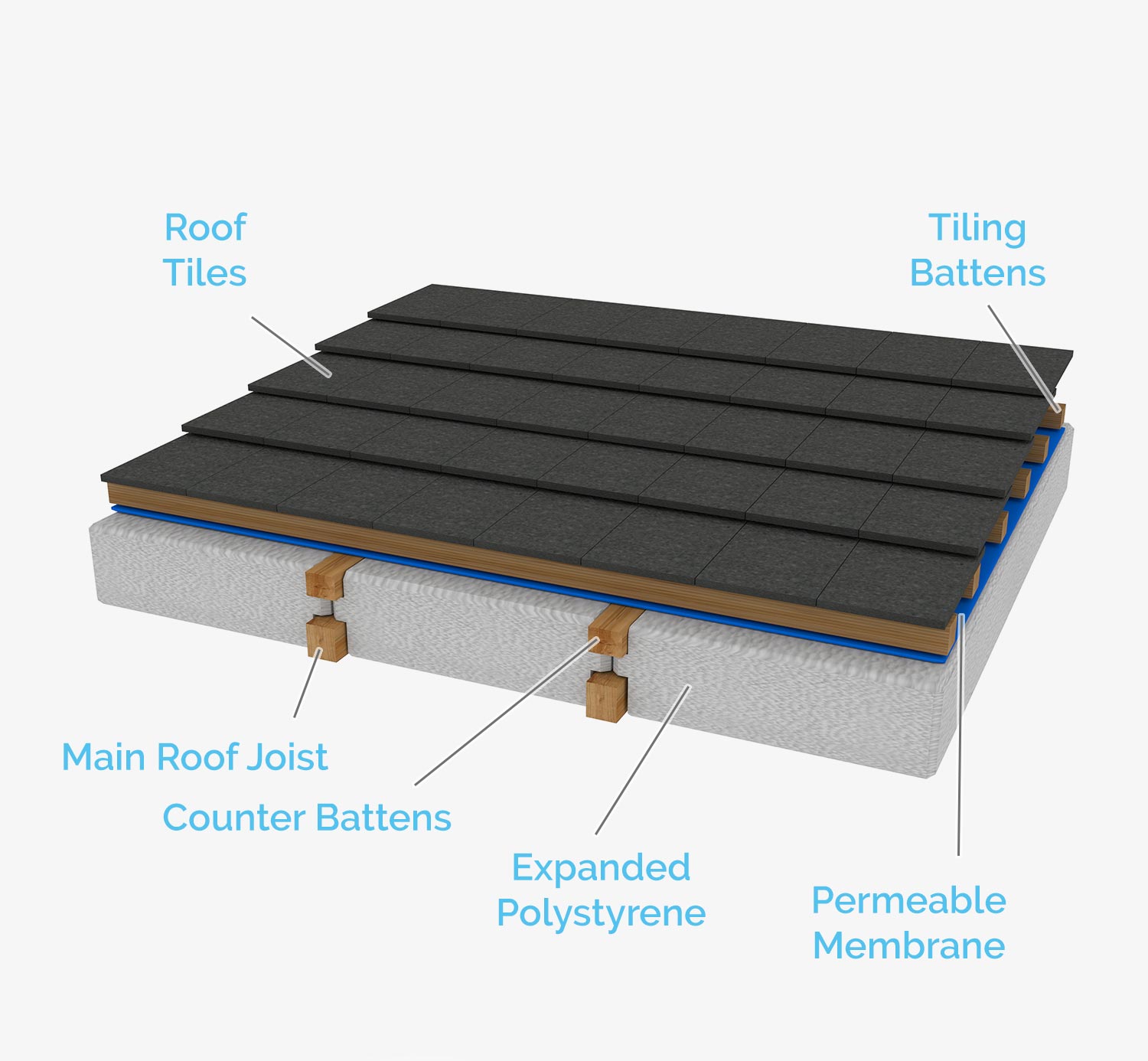

Our pitched roof panels are designed for use in warm pitched roof applications to provide a high level of insulation and are designed to insulate both the rafters as well as the roof and prevent the rafters forming a cold bridge.

When used in conjunction with a breathable membrane such as Roofshield or an equivalent it removes the need for ventilation of the roof void.

S and B EPS pitched roof panels are manufactured in various sizes to suit most rafter centres, thicknesses and edge profiles to suit nominal 38 or 50mm rafter centres plus, if required, an edge detail can be produced to accommodate double lapped rafters.

S and B EPS pitched roof panels are available in the following dimensions.

Length: 1200mm

Width: to suit 400,450 and 600mm rafter centres with standard thicknesses being 90 and 140mm other thicknesses are available on request.

All S and B EPS pitched roof panels are manufactured using fire retardant grades of EPS as standard, without the use of CFC and HCFC gases.

Common grades used are EPS 100E, EPS 150E, EPS 200E and Lambdatherm our high thermal performance material.

S and B EPS pitched roof panels are designed to accommodate 400, 450 and 600mm rafter centres as standard.

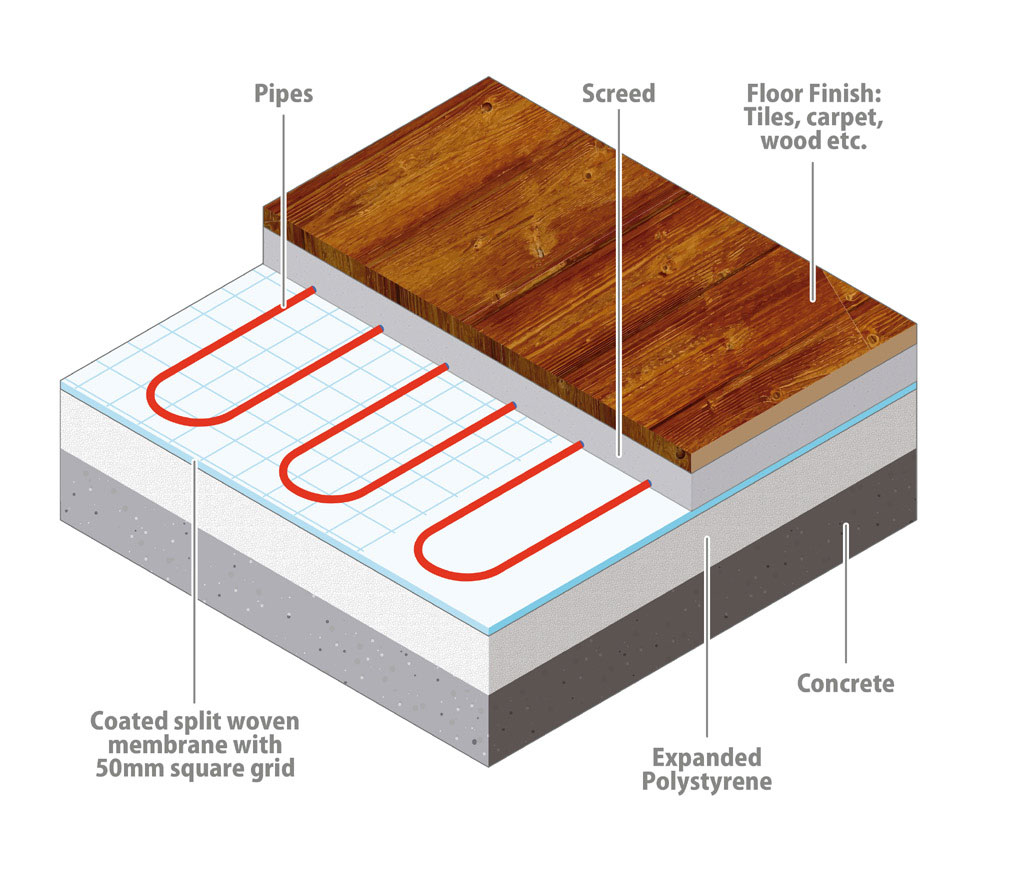

When installing S and B EPS pitched roof panels the first run of panels should be installed from the ridge, ensuring that the first panel matches the pitch of the roof, then continue the run to the eaves, ensuring that the rafter end again matches the required angle at the eaves.

This procedure should then be followed on each successive run until completion, ensuring that any gaps are filled with a suitable expanding foam sealant. Then a 38 x 50mm treated timber batten should be attached to the rafter tops at the eaves, abutting the last run of roof panels providing a stop end to retain the panel in position.

The panels are then secured by a 38 x 50mm wide treated counter batten positioned in the recess [as shown in the diagram, left] formed between two rows of panels.

If required S and B EPS pitched roof panels are available to accommodate lapped rafters, matching the standard profile of our pitched roof panel boards.

A proprietary permeable sarking membrane should be installed over the counter battens in accordance with the manufacturers recommendations, with the tile battens then fixed to the counter battens using 65mm nails followed by the tiles with all work being carried out in accordance to BS 5534: Part 1.

Grades

S and B EPS warm pitched roofs are available in:

EPS 100E

EPS 150E

EPS 200E

Lambdatherm® Elite

To discover more about the benefits of S and B Roofing Solutions, call today on 0191 250 0818

Technical Information

| Features | Grades EPS | Lambdatherm® | |||

|---|---|---|---|---|---|

| EPS100E | EPS150E | EPS200E | ELITE | 150E | |

Thermal Conductivity [k] value W/mk (10.C mean) |

0.036 | 0.035 | 0.034 | 0.030 | 0.031 |

Compress Strength kPa Min (at 10% compressivew strengths) |

100 | 150 | 200 | 100 | 150 |

Cross Breaking Strength kPa Min |

150 | 200 | 250 | 150 | 200 |

Safe Working Load kPa at 1% nominal compression |

45 | 70 | 90 | 45 | 70 |

Vapour Diffusion Resistance factor µ1 |

30-70 | 30-70 | 40-100 | 30-70 | 30-70 |

Vapour Permeability omg [pa.h.m] |

0.009 to 0.020 | 0.009 to 0.020 | 0.006 to 0.015 | 0.009 to 0.020 | 0.009 to 0.020 |

Colour Guide

| Identification / colour coding of products manufactured to BSEN 13163 | ||||||||

|---|---|---|---|---|---|---|---|---|

| EPS 70E | 2 x brown stripes & 1 red stripe | |||||||

| EPS 100E | 1 x black strip & 1 red stripe | |||||||

| EPS 120E | 2 x green stripes & 1 red stripe | |||||||

| EPS 150E | 1 x yellow strip & 1 red stripe | |||||||

| EPS 200E | 2 x black stripes & 1 red stripe | |||||||

| EPS 250E | 1 violet stripe & 1 red stripe | |||||||

| EPS 500E | 2 x black stripes & 1 red stripe | |||||||

Product Files

Case Study

FAQs

Question 1

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Question 2

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Question 3

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.